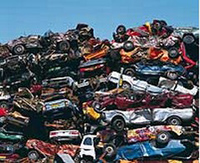

The auto recycling process

The first step is a detailed inspection. If the car is repairable, a decision must be made whether the initial purchase price plus the estimated cost of the repair will be less than the resale value. The is generally only the case when the car has relatively low mileage and minimal body damage.

Ninety percent of the cars we haul do not meet this test. They are taken to a recycling plant where all of the fluids are drained -- gas, oil, antifreeze, brake and transmission fluids and lubricants. Some of these liquids are considered hazardous and must be carefuly stored and then safely shipped to processing plants. The gas is filtered and reused in our own tow truck.

Next the engine and transmission is lifted from the chassis and reusable parts removed, cleaned, tested and stored in a warehouse for sale to auto repair garages. Some parts are not resold, but their contents are recycled through various chemical and manufacturing steps. This includes the battery, tires, air bag cartridges, mercury-containing switches, lead parts, and catalytic converters. Finally the body is crushed and the crushed car is then put through a huge shredding machine which reduces it to golf ball sized chunks of metal.

This recycling process recovers 75 percent of the vehicle by weight, which is a greater percentage than any other type of recycling process. (Even aluminum can recycling, the next most efficient item, recovers only 61%.) Automotive recycling is the 16th largest industry in the United States, estimated to be a $25 billion per year industry. Recycling autos provides enough steel to produce almost 13 million new automobiles, while generating jobs for 46,000 people.

| Copyright © 2014 Peter H. Boynton, New Seabury, Massachusetts |

|---|